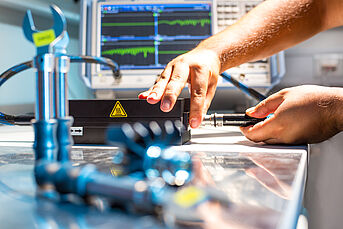

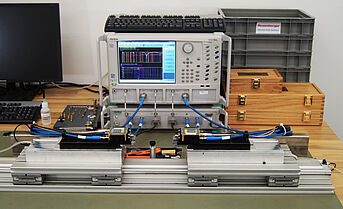

Since its foundation in 1991, Rosenberger Messtechnik Sachsen has developed into a valued partner for research and industry in the field of high-frequency measurement technology.

As of July 2023, Rosenberger Messtechnik Sachsen GmbH and the parent company in Fridolfing will operate jointly under the name Rosenberger Hochfrequenztechnik GmbH & Co. KG. This decision represents a sustainable basis to secure the specific strengths of the Radeberg site as a plant and to continue to be successful together.

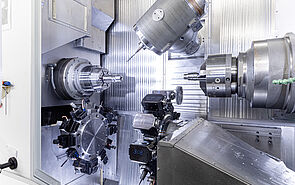

As a full-range supplier for measurement technology, Radeberg consistently maps comprehensive value chains and accompanies its customers throughout the entire process - from development and design to the production of prototypes and initial samples to series production.

For specific requirements, individual solutions can also be developed and built in a timely and cost-optimized manner. The Radeberg site has local know-how and competence and at the same time benefits from the global network of the Rosenberger Group.